Industrial refrigeration

Sustainable

cooling solutions :

New system to make the compression cycle of refrigerants more efficient

- Electricity consumption related to refrigeration, air conditioning, and heat pumping currently represents around 17% of global electricity consumption*. This will increase significantly over the next years due to increasing global temperatures, economic development and urbanization. Refrigeration and cooling will not only challenge the global energy supply but could also significantly increase CO2 emissions if no actions are taken. The European Commission has established ambitious goals in its European Green Deal focused on making Europe the world’s first climate-neutral circular economy by 2050. Enhancing refrigeration and cooling’s energy efficiency and addressing refrigerants will play an important role.

* Source: International Institute for Refrigeration IIR – France, www.iifiir.org

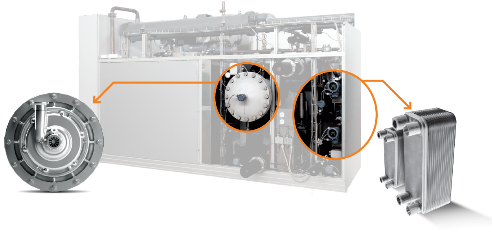

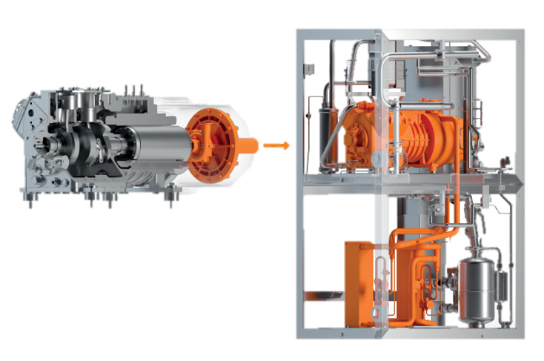

- Turboalgor has patented a system that can make the compression cycle of refrigerant fluids more efficient, applying a technology used for many years in automotive sector, the turbomachinery.

- Improves the cooling capacity (up to +56%) and the energy efficiency (up to +23%) of both old and new compression refrigeration systems.

- Operates with electric power >20kW and with fluorinated refrigerants. Still under development: a new product range operating with natural refrigerants and electric power <20kW (Vireco Project).

Click here and here for more information

- Economic and environmental benefits due to energy savings, and reducing main compressor electric absorption

- Example: DI BATTISTA FOOD with an automated warehouse with 14,000m² of refrigerated area and 10,750m3 of cold storage , able to supply up to 1,500 deliveries per day in the south of Italy: reduced energy consumption of the refrigeration system by about 30%, which has translated into economic savings of around 20%.

Click here to download the case study