Industrial refrigeration

Sustainable

cooling solutions :

Industrial Freezing, Cooling and Heating with environmentally friendly refrigerants

- At a time where focus and efforts are increasingly aimed at reducing energy consumption and carbon footprint overall, certification systems have also been developed in relation to building stock with the purpose of projecting, dimensioning, constructing and finally documenting buildings while focusing on sustainability.

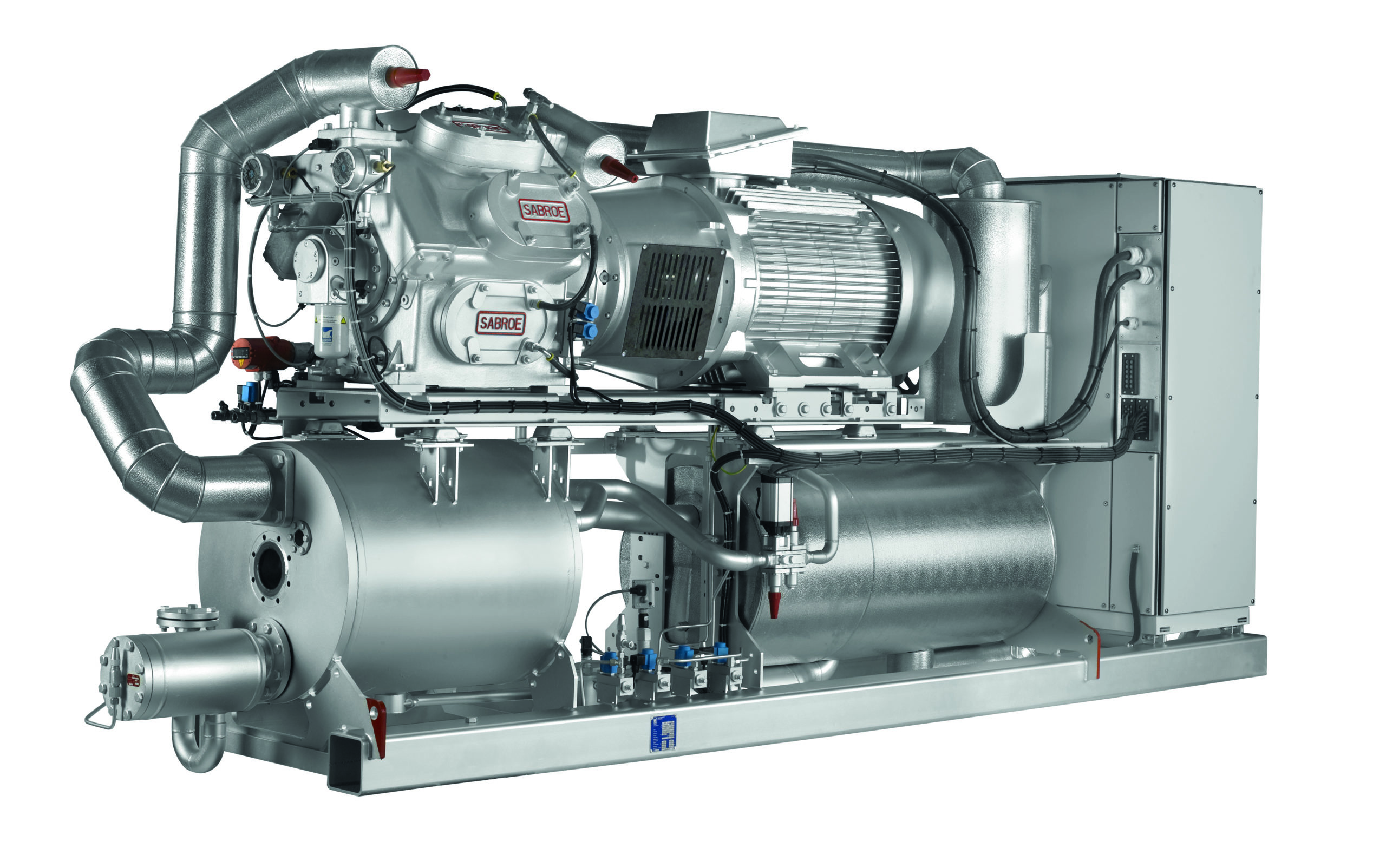

- BREEAM is such a system and is being used globally. In addition to the highly technical specifications, the BREEAM system also deals with softer values ensuring sustainable working conditions. The Dutch version, BREEAM NL, has recently been used at the abattoir and meat processing company Westfort IJsselstein, where Johnson Controls – Sabroe Products Netherlands in collaboration with VHI Koudetechniek has supplied the complete freezing, cooling and heat pump solution with the natural and environmentally friendly refrigerants CO2 and NH3 (ammonia).

- The complete plant will be supplying cooling and heating capacity for four different temperature levels, ranging from -52°C to +75°C, and is exploiting the broad range of industrial reciprocating and screw compressors from Sabroe Factory Denmark.

- The ranges covers:

- CO2 Ultra-low temperature at -52°C for product freezing.

- NH3 (Ammonia) low temperature at -30°C for cold storage.

- NH3 (Ammonia) medium temperature at -10°C for process cooling and cold storage.

- NH3 (Ammonia) high-temperature heat pump at +75°C for heating and hot water production.

- As all temperature levels, from the lowest to the highest, are connected in a cascade system, all normal waste energy is being utilised by the next higher level. In combination with the natural, high-performing refrigerants, CO2 and NH3, the overall performance, energy consumption and environmental footprint are so efficient that the refrigeration and heat pump plant, along with the entire building solution, has reached the highest level of BREEAM NL certification « Excellent ».

- The complete plant solution has been designed and calculated in a joint operation between VHI Koudetechniek and Johnson Controls – Sabroe Products Netherlands.

- Facts:

- Ultra-low temperature freezing capacity 4,000 kW

- Low temperature freezing capacity 1,000 kW

- Medium temperature cooling capacity 10,000 kW

- Heat pump capacity 1,600 kW

Click here and here for more information

- Flexible, sustainable and future-proof refrigeration and heat pump solution with the lowest possible energy consumption, secured by the sustainable and environmentally friendly refrigerants CO2 and NH3 (Ammonia) and powered by high-efficient Sabroe compressors.

- The new factory will be self-sufficient with the heat pump producing hot water for heating purposes throughout the year. It will not require further heat generated by fossil fuels.

- The heat generated by the heat pump equals potential savings of approximately 1,190,000 M3 of natural gas.

- If needed, the plant can be extended to supply heating capacity to a local district heating network.

Click here to download the case study