Commercial Refrigeration

Sustainable

cooling solutions :

Energy savings of >30% with water loop and system integration in supermarkets

On average, 50% of the energy in supermarkets is consumed by refrigeration systems to keep food safe, fresh and healthy. Saving energy is therefore a top priority for retailers as it represents a major cost factor. Demonstrating energy and emission savings also contributes to a positive image of the retailers, increasing attractivity for consumers. Finally, with the large number of retail and wholesale enterprises in Europe (around 5.4 million according to EuroCommerce*) and the availability of dedicated technologies, this sector has a major role to play when it comes to achieving the European energy and climate goals.

- Supermarket in Northern Germany (average outdoor temperature: 8.8°C), built in 2016

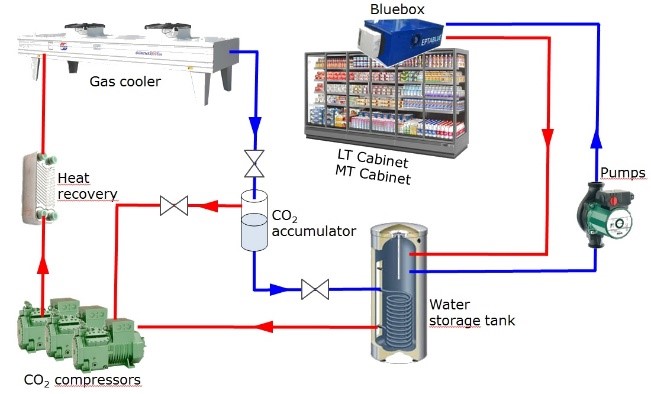

- Water loop system to cool 17 low temperature cabinets and 23 medium temperature cabinets, all using HFC R-410A as a refrigerant. Charge sizes could be reduced significantly ranging from 1/5 to 1/3 compared to those of traditional systems.

- All cabinets equipped with electronic expansion valve (EEV) and brushless DC compressor (BLDC) with a cooling capacity of around 2 kW at 18°C ambient temperature.

- Modulation of the EEV and BLDC compressor to avoid on/off operation, allowing for an increase of the evaporation temperature by approx. 6K from -11,3°C to -5.5°C.

- Water-Water heat pump using CO2 as a refrigerant with two goals:

- To cool the water of the water loop system down to 16-18°C

- To recover, upgrade and transfer the heat from the water loop for heating purposes and sanitary hot water production

Click here for more information

- Energy savings: each cooling cabinet saves around 34% energy (compared to on/off cabinets) due to the increased evaporation temperature which effectively means that less compressor work is required to achieve the desired cooling effect.

- Synergies: the CO2-based heat pump enhances the energy efficiency of the entire shop by recovering most of the heat rejected by the cooling cabinets to use it for space heating and sanitary hot water production.

- Lifetime: compressor modulation allows to reduce frequent on/off operation with the benefit of reduced wearing and servicing, increasing the useful lifetime of the equipment.

Click here to download the case study