Commercial Refrigeration

Sustainable

cooling solutions :

Optimized and innovative control and monitoring solution, for transcritical CO2 booster systems

Client’s site is a medium size supermarket, located in the Italian Alps, North of Venice. The focus was to support the customer’s desire to switch towards a natural refrigerant system, while facing the most common challenges: efficiency versus complexity of the system and its maintenance costs.

- As a result of the mild temperatures of the location, the system designer opted for a transcritical CO2 booster system which incorporates a liquid ejector.

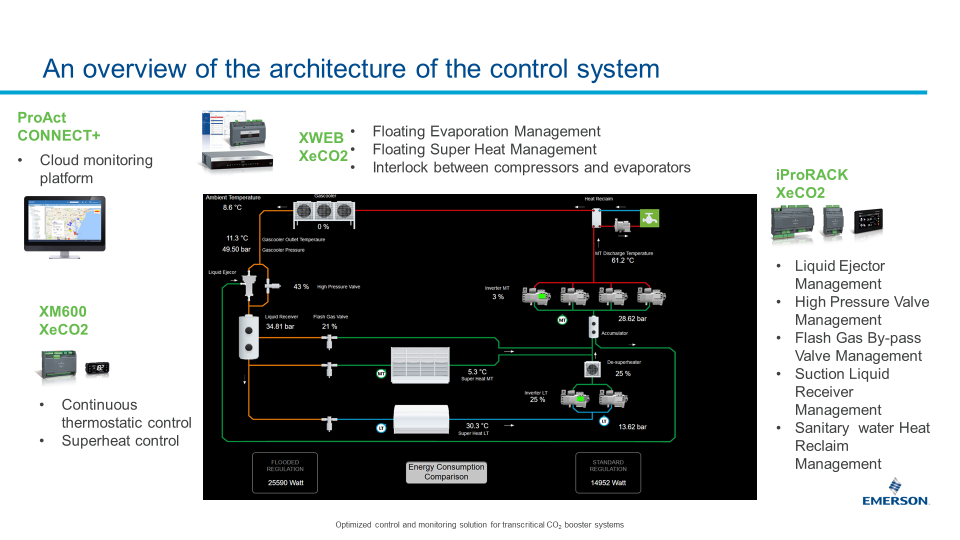

- Emerson developed an innovative electronics ecosystem, XeCO2 hosting the functionalities required to support the ejector’s special requirements.

- Installed into the transcritical CO2 booster system of the supermarket, XeCO2 ‘s main objective was reached: delivering the expected savings and preserve the system reliability, by coping with continuous fluctuations of operative conditions. The constant bi-directional communication among supervisory system, compressor rack controls and refrigerated display case controls, allowed to maximize the benefit of the liquid injector, while preserving the reliability of the entire system.

- Case controls feed data to the supervisor that defines when there is room to increase the evaporation temperature and save energy. After that condition is verified, a setpoint change is dispatched to the compressor rack control, in charge of maintaining the desired evaporation temperature. This also applies in the opposite direction when there is a need for more refrigeration capacity, at the expense of increased energy use.

- The rack controller monitors that there is a regular flow of refrigerant back to the compressors, imposing changes to the case controls, to preserve the system reliability.

- Featuring an easy setup and user-friendly interface, the XeCO2 supervisor helped the client to have easy remote access to the refrigeration system and to optimize the control system for energy efficiency and overall reliability.

Click here for more information

- CO2 as natural refrigerant solution

- Improved system efficiency

- Innovative algorithm that allows staged heat recovery for sanitary water and heating purposes

- Safe, reliable operation of the system – compressor protection

- Flexible control system, applicable to most of the already existing CO2 architectures

- Electronics ecosystem fully optimized for the CO2 natural refrigerant

- Reduced maintenance activities on the system

- User-friendly interface

- Easy setup

- Remote access

Click here to download the case study