Thermal comfort

Sustainable

cooling solutions :

Closing the loop: Refrigerant reclamation and reuse as contribution to a circular economy of refrigerants

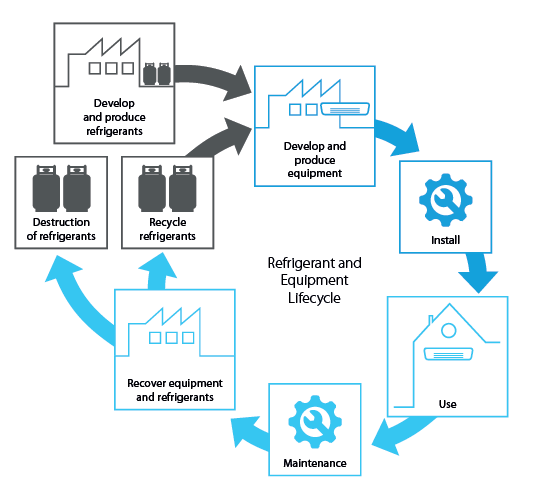

With the EU F-Gas Regulation and the global Kigali Amendment to the Montreal Protocol, both introducing a phase-down of HFC refrigerants, reducing the climate impact of refrigerants has become an essential part of sustainable cooling. Development and use of refrigerants with a lower global warming potential (GWP) are a typical example of how this goal can be achieved, but should be complemented by a life cycle approach, investing into refrigerant recovery, recycling, reclaim and reuse of refrigerants. Such an approach will not only contribute to achieving the phase-down on a European and global level, but also to resource efficiency and to the Sustainable Development Goal (SDG) 12 on sustainable consumption and production.

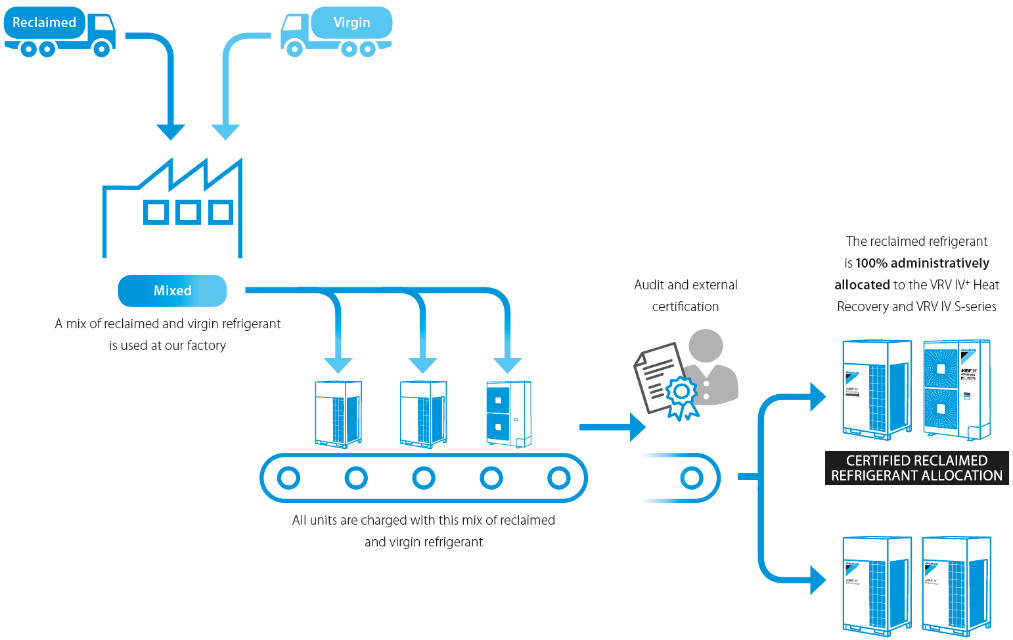

- “Certified Reclaimed Refrigerant Allocation” with refrigerant recovery, reclaim (high quality recycling).

- Currently applied to Daikin VRV IV+ heat recovery, VRV IV S-series and Daikin Applied Chillers.

- An independent laboratory first assesses whether the reclaimed refrigerant is of the same quality as virgin refrigerant. A mix of new and reclaimed refrigerant is then used at the factory to charge the units.

- For the moment, the process is used for HFC refrigerants R-410A and R-134a, but the program has large potential to be expanded to other refrigerants in the future.

Click here more information

- By manufacturing with reclaimed refrigerants, recovered refrigerant is reused instead of being destroyed and production of new refrigerant is avoided

- In 2019, the first year of the launch of the “Certified Reclaimed Refrigerant Allocation” programme, the production of over 150,000 kg of new refrigerant was avoided.

Click here to download the case study